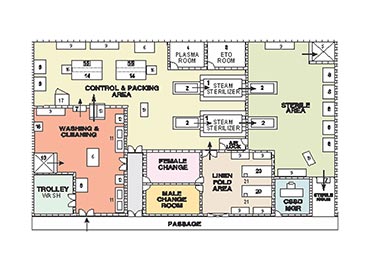

Hospital infection control is a serious problem, which no Hospital Administrator can afford to ignore. Proper attention needs to be focused on the system of Cleaning, Disinfection, Packaging, Sterilization and Storage of different surgical appliances and instruments.

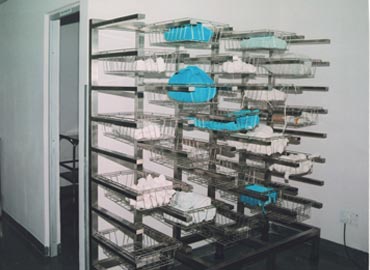

The continuous advancements made in the field of Bio Medical Engineering have resulted in the development of a range of surgical appliances and instruments with very intricate and delicate profiles. Any sterile supply chain must have a system, which can clean and disinfect these components with a very high degree of accuracy and repeatability.

Machinfabrik’s “DISINFECTOMAT” Washer Disinfectors have been designed with just that in mind. The system is not only flexible but also very user friendly to take care of your every need.