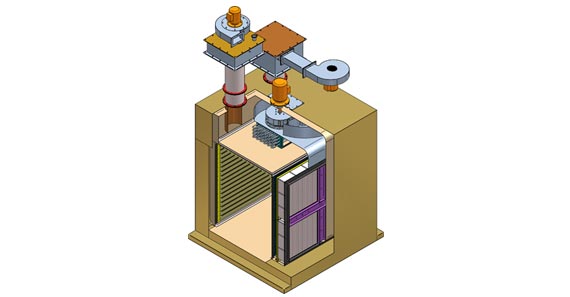

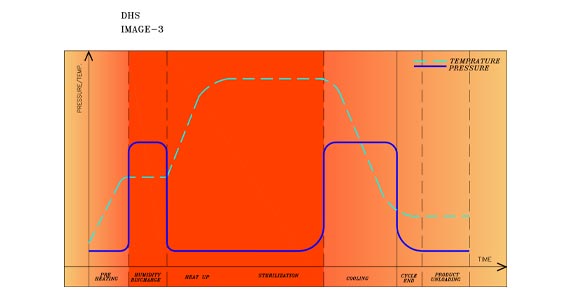

Sterilization by dry heat has become increasingly popular worldwide due to two reasons first the need to sterilize small objects, particularly ampoules, syringes and secondly for de-pyrogenation of manufacturing apparatus which is not possible in a steam sterilizer. Another advantage of this method of sterilization is that objects which are damaged by water or steam e.g. powder or ointment can be sterilized provided the heat penetrates to all parts of the substance. The distinctive feature of these sterilizers lies in particle contamination class. We ensure a particle contamination level in the chamber that does not exceed the values prescribed by class 100: not even during transient phase, such as heating and cooling during which the filters can release considerable amounts of practices due to temperature related deformations. Special air flow technique guarantees over-pressure in the chamber throughout the cycle thereby assuring sterile integrity of the load, These sterilizers are designed to meet the stringent requirements of the pharmaceutical and medical device industry and are available in different configurations to meet specific temperature and cycle time requirements. These sterilizers represent the ideal solution for any production where the variability of products, batches and formats does not allow the use of continuous sterilizers such as tunnels.

-

Empty glassware (e.g. Vials, Ampoules and bottles).

-

Containers and metallic components.

-

Thermo stable basic pharmaceutical products and chemical compounds.

-

Non-aqueous liquid material (e.g. Oils, glycerin, etc.)

-

Metal trays.

-

cGMP compliant easy to clean with smooth surface and rounded corners

-

Special gasket system to avoid any air release or cross contamination between the chamber and the external environment.

-

Expansion compensation structure which prevents thermal vibration.

-

Contamination seals to prevent air transfer when the sterilizer has been installed between two areas of different contamination levels.

-

Incolloy sheathed heating elements for reduced particle generation and longer life.

-

Fresh air controlled cooling cycle.

-

Monitoring ports for testing fresh air, exhaust and recirculating HEPA filters.

-

Automatic self-regulating pressure balancing.