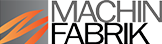

AQUACLAVE is designed to meet the challenges of new flexible packaging materials and sealing technologies, making it necessary for users of Pasteurization / Sterilization processes to evolve processing systems which are more accurate, flexible and versatile. The AQUACLAVE system is most useful for neutral pH and preservative free product. Superlative temperature uniformity guaranteed. AQUACLAVE machines ensure high efficiency and reliable performance specially designed to solve Pasteurization / Sterilization problems of food products packed in Plastic/Glass/ Tin Container or Flexible Pouches. AQUACLAVE ensures counter balancing of pressure formed inside containers during the process thereby avoiding breakages, loss of tightness of closures and deformation

-

Dairy- Flavoured Milk, Fresh Cream, Fresh Milk, Paneer.

-

Indian Sweets- Rasmalai, Shrikhand, Gulabjamun, Basundi, Rasgulla.

-

Processed Foods- Curried veg, Non- veg dishes, Various RTE products, Various Chicken /Lamb / Pork products.

-

Beverages- Various Fruits Juice, Coffee and Chocolate Drinks.

-

Fresh Fruits- Slices, Pulp.

-

Coconuts- Cream, Water Milk.

-

Vegetables- Various Beans, Corns etc.

-

Indian Culinary Pastes- Various Pastes, Soups Baby Foods.

-

SAL up to 10-6

-

Programmable temperature ramps with a cycle range between 50oC to 121oC to suit variety of products.

-

Variable counter pressure programs.

-

Efficient use of steam, cooling water and circulation water.

-

Completely made form stainless steel.

-

Minimal thermal shock as heating medium (water) and product temperature increase and decrease together.

-

Sterile water for cooling as per International norms.

-

Temperature accuracy +/- 0.75 o C & Pressure accuracy +/- 50mbar.

-

F0 value for each cycle available on printer.

-

Process flexibility for different products and packing.

-

Absolutely no distortion of product primary package.