All over the world packaged food products and ingredients are being extensively used. Here spices, herbs, seeds, nuts, dry fruits and dehydrated vegetable substances play an important role to impart aroma, flavor and color. There is a very high tendency for pathogens like yeasts, molds, spore formers, etc. to get into the food supply. This contamination could be due to soil, water birds, rodents, etc. These microbes remain in the food product / ingredients after processing since most manufacturers follow simple treatments at low temperature. If left untreated, there is continuous growth of microbes and pathogens, which can lead to spoilage of the food and even harm the health of the consumer. For this reason regulators are becoming more and more stringent and strict guidelines are being formulated for food products and ingredients.

-

Spices.

-

Herbs.

-

Cereals.

-

Dry Fruits

-

Nuts

-

Organic/Inorganic granular material & Dry Fruits.

-

Fast throughput for maximum productivity.

-

Hygienic design to ensure zero contamination during processing.

-

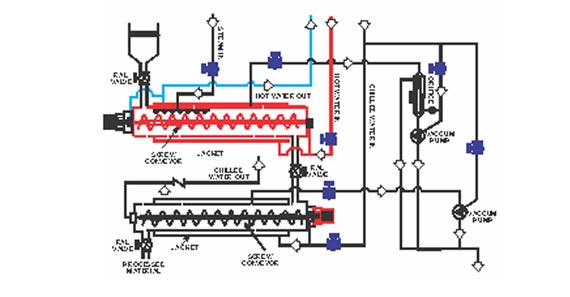

Product is decontaminated, dried and cooled in one single machine.

-

No loss of flavor, oils, color and aroma for best results.

-

Deactivation of enzymes which is not possible with other methods like ethylene oxide and irradiation.

-

Fully automatic operation with minimal operator intervention.

-

Data-logging systems which allow you to store all your critical process parameters.