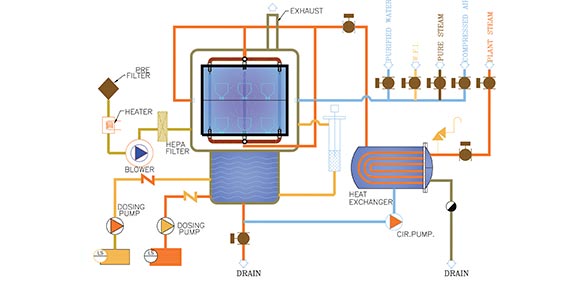

All areas of production in any pharmaceutical industry increasingly demand qualification and documentation of the cleaning processes. Years of experience with international customers has made Machinfabrik a reliable partner for validated cleaning. Our washers have been designed to meet and exceed the growing cGMP requirements of the Biopharmaceutical industry. Working in cooperation with users, our equipment has been developed to satisfy the unique demands and stringent regulations of the industry. We can provide a complete solution supported by need analysis and system design to suit your requirements. Our systems are based on compatible modular units that can quickly be integrated and installed to form complete customized solution based solely on your needs. All machines are based on high-performance cleaning modules a rinsing system and an integrated air-drying system.

-

Glass bottles.

-

Containers.

-

Filling Machine Parts.

-

Carboys.

-

Glassware’s.

-

Pipettes.

-

Fermentors.

-

Pump Parts.

-

Filter Housings.

-

Test Tubes.

-

Petri Dishes.

-

Sterility Manifolds.

-

Solutions in glass ampoules, vials, glass & bottles.

-

The space saving design ensures that the cleaning apparatus uses very little floor space but at the same time gives you maximum cleaning flexibility.

-

Standard machines can be integrated with a range of trays and racks to handle your diverse needs.

-

A wide variety of standard cleaning programs offer you different options to decide on the most suitable washing cycle for your components.

-

The cleaning chamber has corners with radius and sloping bottom for full drain ability.

-

High Volume of the Cleaning Fluid at accurate pressure to ensure a gentle but effective washing action.

-

Steam heating arrangement for cleaning medium for best results.