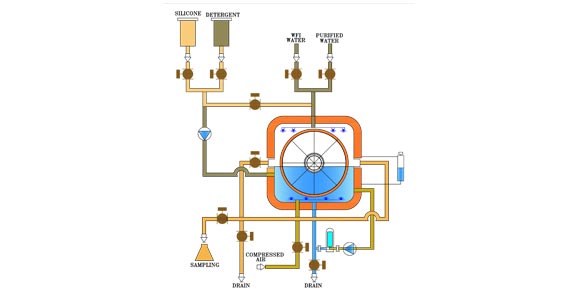

Processing of electrometric closures is of high concern since they play a significant role in the quality and life of the final product. The need for correct processing technology is even more important considering the complexities in the compounding of the elastomers used for the closures and the non-compliance to GMP by the manufacturers of these closures. The BUNG PROCESSOR is designed for a unique dual operation and works as a Steam –Sterilizer to save additional investment and space.

-

Solid materials.

-

Porous materials like garments, fabrics, etc.

-

Closures, Vessels, Machine and change parts.

-

Empty Glassware, Utensils, Instruments.

-

Solutions in glass ampoules, vials & bottles.wwwnnnnnnn.

-

Filters and respective accessories.

-

Processing of closures.

-

A unique Triple Punch Cleaning system is implemented to ensure thorough cleaning and sterilization of the closures.

-

The CLOSURE PROCESSOR is fitted with a Clean in Place (CIP) system for washing the chamber and the rotating carriage to prevent the released dirt from being carried over from one phase to the subsequent phase.

-

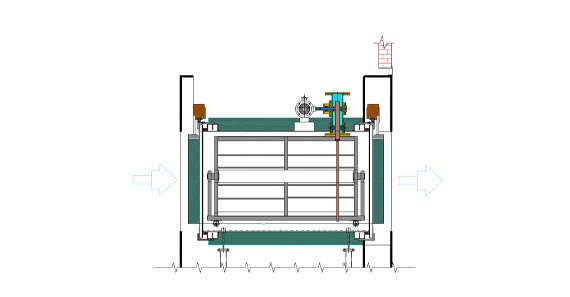

Machinfabrik has developed friction drives to prevent direct metal to metal contact for superior processing.

-

Sampling ports for online monitoring of the cleaning efficiency.

-

Temperature and pressure ports for monitoring and validating the sterilization process.

-

This Rotating Carriage ensures smooth and easy loading and unloading of closures. The design of the basket guarantees effective cleaning and sterilization of elastomeric closures.

-

After complete processing the stoppers are unloaded in the sterile area under a fixed laminar flow unit without operator intervention in pre-sterilized containers or bags.