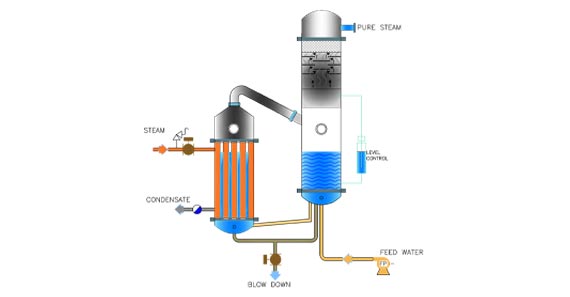

As the pharmaceutical industry continues to grow and change, Machinfabrik strives to deliver superior quality products that are manufactured in accordance with cGMP. By choosing Machinfabrik Pure Steam Generator you are taking a proactive step in eliminating instance of contamination thus safe guarding your company and the end user from products that could be potentially harmful. The sterilization process at a pharmaceutical industry requires high quality pure steam with accurate pressure control and fast response times. Machinfabrik Pure Steam Generator is capable of producing pyrogen-free sterile pure steam that when condensed meets all USP requirements for use in steam sterilizers, critical area humidification and routine SIP.

-

Complies with all requirements of EN285 for sterilization application.

-

Double tube sheet construction heat exchangers for maximum security.

-

Multi-direction baffles and cyclone separator for effective pyrogen entrainment.

-

Degassing system for removal of dissolved gases from generated pure steam.

-

Conductivity sensor for monitoring conductivity of in-feed water & condensate of generated pure steam.

-

Sampling condenser with sampling device to check quality of generated Pure Steam.

-

Steam testing port to check quality of generated pure steam.

-

Electro-polished surfaces with finish better than 0.3 micron for superior hygiene.

-

Sanitary tubes and fittings with dead < 1.5 D slope > 2% for maximum drain ability.

-

Flow transmitter on feed water line to monitor quantum of generated Pure Steam (optional)