Today, manufactures of food products and ingredients use complex processing equipment’s and have to maintain the highest level of hygiene to ensure that there is no contamination during the process. Food regulators have also become strict and stringent guidelines have been formulated to safeguard the health of the consumer. Keeping this in mind, Food Technologists and Engineers have to be cautious about selecting the processing systems and utilities, which come in contact with the product. Here, the quality of steam injected in the product for cooking requires careful monitoring. The steam injected should be free of all volatile impurities and chemical.

Machinfabrik offers you a Clean Steam Generator for exactly this application. The system is built from stainless steel for superior hygiene and employs a unique pyrogen entrainment and purification system that guarantees sterile and pyrogen free steam for your most critical processes. Here water, pretreated with process like reverse osmosis is used as a feed and boiler quality steam is used to heat the feed water and generate vapor in a shell and tube construction evaporator. The generated vapor is then led to a separator column where the steam is purified. The system is fully automatic and has online monitoring of conductivity for high process assurance.

-

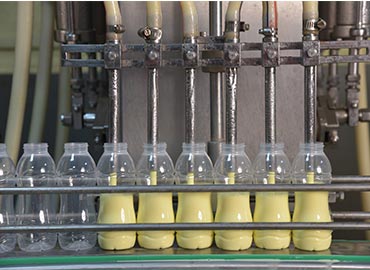

Jams

-

Sauces

-

Fruit pulp.

-

Fruit juices

-

Purees. wwwnnnnnnnwertyuwdradwertyuiopqwertyupqwertyuop.

-

Wide range of models to suit your demanding process needs.

-

Stainless steel construction for superior hygiene.

-

All pipes, fittings and valves are of sanitary design to ensure no risk of contamination.

-

Fully automatic, PLC based controlled system to ensure high process reliability.

-

Comprehensive process documentation and data-logging systems for high process assurance and regulatory compliance.

-

On-line monitoring of conductivity for immediate warning.

-

Energy efficient design for maximum heat recovery from the heating boiler steam.