The production programs in the pharmaceutical industry are aimed at maximum safety, top quality and high economy. This applies in particular to the sterilization process. Steam Sterilizer continues to be one of the ancient but widely used sterilization techniques in the Life-Science & HealthCare Industry. The process systems now have to meet the most exacting demands for temperature and pressure / Vacuum control and process documentation. A sterilization systems represents Therefore, Machinfabrik takes measures to ensure that our Sterilizers provide and life cycle economy. Every Sterilizer is produced to your specifications and needs. Flexible options allow selection of the right equipment for each specific sterilization load and packaging.

-

Solid materials.

-

Porous materials like garments, fabrics, etc.

-

Closures, Vessels, Machine and change parts.

-

Empty Glassware, Utensils, Instruments.

-

Solutions in glass ampoules, vials & bottles.

-

Filters and respective accessories.

-

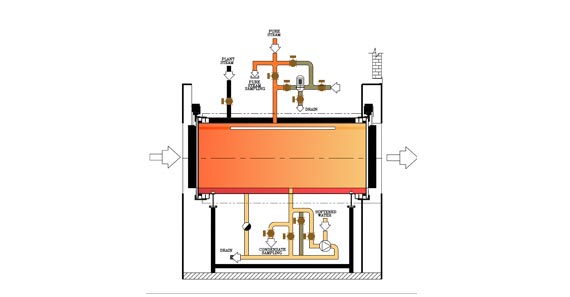

Chamber with sloping bottom & recessed drain connector for effective condensate removal.

-

Three designs of jacket- Straight profile, u-profile and dimple for different applications.

-

Machine gasket groove formed on CNC machine for superior gasket performance.

-

Double stage vacuum pump with unique water safer arrangement.

-

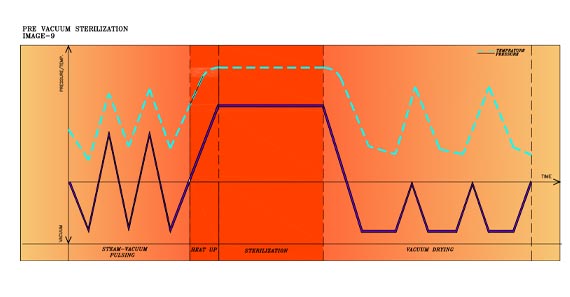

Dynamic steam and vacuum programs for short equilibration time and excellent temperature uniformity.

-

Air detector device meets requirements of EN285.

-

Comprehensive safety features for operator and product safety.

-

Hot air drying in combination with vacuum for best drying results.