Cleaning is an integral component of virtually all instrument-reprocessing guidelines. If labeled for reuse, instruments require manual pre-cleaning, using a brush and detergent solution, to remove gross patient debris. Because complex instruments may remain contaminated with patient debris even after manual brushing, most reprocessing guidelines recommend using ultrasonic energy to remove fine debris that might otherwise be inaccessible and remain on the instrument. Unless the cleaning process effectively removes microorganisms and organic debris from even the most inaccessible surfaces of a contaminated instrument, the sterilization process is likely to fail. Developing more advanced cleaning technologies that can adapt to even the most complex surgical instruments and clean their most inaccessible internal surfaces is crucial to the prevention of patient infection.

-

Fully automatic and user friendly operation.

-

Fully transistorized (MOSFET) based in built compact generator for conversion of standard frequency into ultrasonic frequency.

-

Automatic tuning of ultrasonic frequency independent of water level, temperature and load which is to be cleaned.

-

High performance PZT type sandwiched bonded transducers provide uniform ultrasonic vibrations in the cleaning bath.

-

Removes gases in the water for optimized cleaning efficiency.

-

All SS contact parts, piping and fitting for superior hygiene.

-

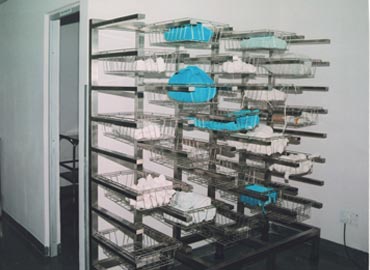

Stainless Steel basket for loading & handling the material.

-

Digital display of temperature and time.